Some concrete is suitable for building construction, others are usually used for road construction. And even the power plant has special requirements on the concrete ration and strength. Different types of concrete are suitable for different applications in various types of construction works. They have different properties and uses.Different types of concrete that will differ based on the constituent material, mix design, the method of construction, the area of application, the form of hydration reaction.

There are many kinds of concrete,such as Normal Strength Concrete,Plain or Ordinary Concrete,Reinforced Concrete,Prestressed Concrete,Precast Concrete,Light Weight Concrete,High-Density Concrete,Air Entrained Concrete,Ready Mix Concrete,Polymer Concrete,High-Strength Concrete,High-Performance Concrete,Self Consolidated Concrete,Shotcrete Concrete,Pervious Concrete,Vacuum Concrete,Pumped Concrete,Stamped Concrete,Limecrete,Asphalt Concrete,Roller Compacted Concrete,Rapid Strength Concrete,Glass Concrete

I will briefly introduce some kinds of concrete that are usually used in the construction site of building or road due to their special characters and features.

Reinforced Concrete

The reinforced cement concrete is defined as the concrete to which reinforcement is introduced to bear the tensile strength. Plain concrete is weak in tension and good in compression.

Hence the placement of reinforcement will take up the responsibility of bearing the tensile stresses. R.C.C works with the combined action of the plain concrete and the reinforcement.The steel reinforcement used in the concrete can be in the form of rods, bars or in the form of meshes. Now fibers are also developed as reinforcement.

Fiber reinforced concrete are concrete that uses fibers (steel fibers) as reinforcement for the concrete. Use of meshes in concrete will give ferrocement.

Whatever be the type of reinforcement used in concrete, it is very necessary to ensure proper bond between the concrete and the reinforcement. This bond will control the strength and the durability factors of the concrete.

Prestressed Concrete

Most of the concrete mega projects are carried out through prestressed concrete units. This is a special technique in which the bars or the tendons used in the concrete is stressed before the actual service load application.

During the mixing and the placing of the concrete, these tensioned bars placed firmly and held from each end of the structural unit. Once the concrete sets and harden, the structural unit will be put in compression.

This phenomenon of prestressing will make the lower section of the concrete member to be stronger against the tension.

The process of prestressing will require heavy equipment and labor skill (jacks and equipment for tensioning). Therefore, the prestressed units are fabricated and assembled on site. These are used in the application of bridges, heavy loaded structures, and roof with longer spans.

Precast Concrete

Various structural elements can be made and cast in the factory as per the specifications and brought to the site at the time of assembly. Such concrete units are called as the precast concrete.

The examples of precast concrete units are concrete blocks, the staircase units, precast walls and poles, concrete lintels and many other elements. These units have the advantage of acquiring speedy construction as only assemblage is necessary. As manufacturing is done at site, quality is assured. The only precaution taken is for their transportation.

Lightweight Concrete

Concrete that has a density lesser than 1920kg/m3 will be categorized as lightweight concrete. The use of lightweight aggregates in concrete design will give us lightweight aggregates.

Aggregates are the important element that contributes to the density of the concrete. Examples of lightweight aggregates are the pumice, perlites, and scoria.

Light weight concrete is applied for the protection of the steel structures and also used for the construction of the long span bridge decks. These are also used for the construction of the building blocks.

Ready Mix Concrete

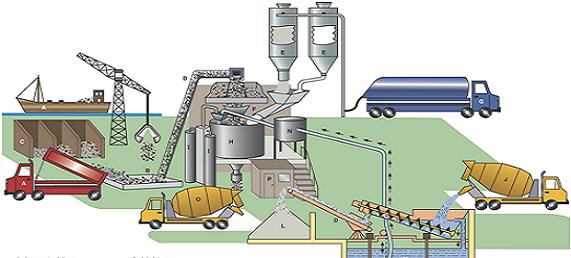

The concrete mixed and soaked in the central mixing station is called ready-mixed concrete.The mixed concrete is brought to the site with the help of a truck-mounted transit mixer. This is once reached in the site can be used directly without any further treatment.

The ready-mix concrete is very precise and specialty concrete can be developed based on the specification with the utmost quality.

The manufacture of these concrete will require a centralized mixing plant. These plants will be located at an adjustable distance from the construction site. If the transportation is too long then it will result in the setting of concrete.Such a time delay problem is to cope with the delay setting due to the use of retardants.

For different construction site,the requirements on the mixing ration,concrete strength,composition of the concrete,no matter the ready mixed concrete or concrete produced on the site. Making a special production design of the concrete batching plant is necessary.Concrete batching plant can be divided into many types, such as dry mixed or wet mixed according to the adding time of the water and additive admixture.But this will usually meet most requirements of the production.

0 Comment