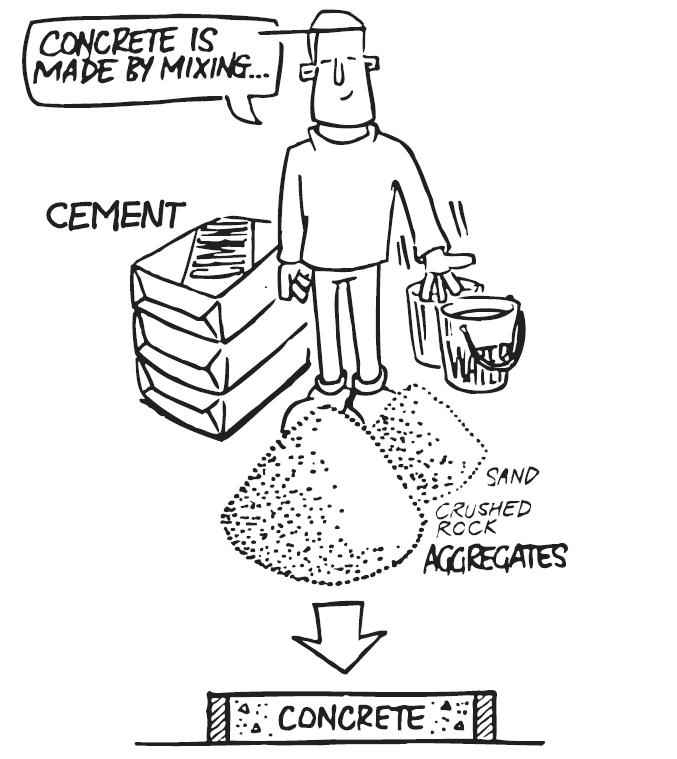

CONCRETE is made by mixing: CEMENT, WATER, COARSE AND FINE AGGREGATES,ADMIXTURES (if required).

The aim is to mix these materials in measured amounts to make concrete easy to process: TRANSPORT,PLACE,COMPACT and FINISH and which will set, and harden, to give a strong and durable product. The relative amount of each material (ie cement, water and aggregates) affects the properties of concrete.

The cement powder, when mixed with water,forms a paste.This paste acts like glue and holds or bonds the aggregates together.

Six major types of cement are sold in Australia:

Type GP (General Purpose Portland cement)

Type GB (General Purpose Blended cement)

Type HE (High Early Strength cement)

Type LH (Low Heat cement)

Type SR (Sulfate Resisting cement)

Type SL (Shrinkage Limited cement)

Each type of cement will produce concrete with different properties.The most commonly used are Type GP and Type GB. Blended cement contains portland cement and more than 5% of either fly ash, ground slag, amorphous silica (eg silica fume), or a combination of these.

Cement should be stored off the ground in a well-aired, clean, dry place. Wrapping the cement bags in plastic sheets gives extra protection.Bulk cement will normally be stored in silos.

Aggregates are of two basic types:

COARSE: crushed rock, gravel or screenings.

FINE: fine and coarse sand and crusher fines.

Sand should be concreting sand and not brickies sand or plasterers sand.

Aggregates should be:

STRONG and HARD so as to give a strong final concrete - crumbly or flakey rock such as sandstone should not be used.

DURABLE to stand up to wear and tear and weathering.

CHEMICALLY INACTIVE so that the aggregates don't react with the cement.

CLEAN since dirt or clay sticking to the aggregates will weaken the bond between paste and aggregates.

GRADED be of a range of sizes so that they fit together well to give a strong and dense concrete.

Rounded aggregates give a more workable mix.

Angular aggregates make concrete harder to place,work and compact, but can make concrete stronger.

Aggregates should be stored where they will remain clean, separated from other materials and dry. If the aggregates are wet, less water should be used in the mix.

Water is mixed with the cement powder to form a paste which holds the aggregates together like glue. Water must be clean, fresh and free from any dirt, unwanted chemicals or rubbish that may affect concrete. Many concrete plants now use recycled water. Always check bore water before use. Don't use sea water in reinforced concrete as it may rust the reinforcing steel.

Admixtures are mixed into the concrete to change or alter its properties, ie the time concrete takes to set and harden, or its work ability.

0 Comment