Introduce

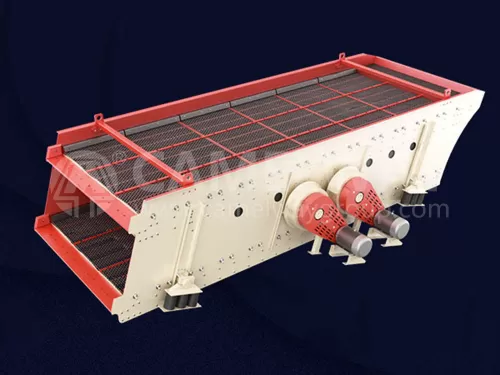

Circle vibrating screen's movement locus is a circumference. It is a new multilayer, high effecient vibrating screen. The circle vibrating screen adopts cylinder eccentric shaft vibrator and partial block to adjust the swing. It can be utilized in mine, core, mill run, construction, electricity and chemical department to take classify function. It has the advantages of reliable structure, strong exciting force, high screen effecient, a small vibrating noise, simple maintenance, safe operation and so on.

The Working Principle of Circular Vibrating Screen

The circular vibrating screen is composed by eccentric vibrator, motor, screen box, base and supporting device.

The eccentric block of the vibrating screen's exciter is driven by the motor via the triangle belt to rotate at high speed. The rotary eccentric blocks produce a great centrifugal force which forces the screening box to move into circles with a certain amplitude. Materials on the leaning screen surface are continuously impacted to do casting or throwing motions. Small particles pass through screen holes when meeting the screen surface, thereby completing the separating process of the circular vibrating screen.

The Types of Vibrating Screen

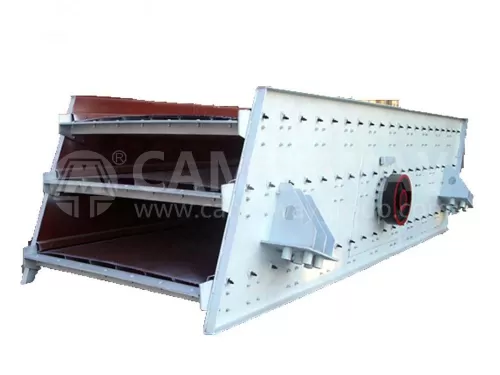

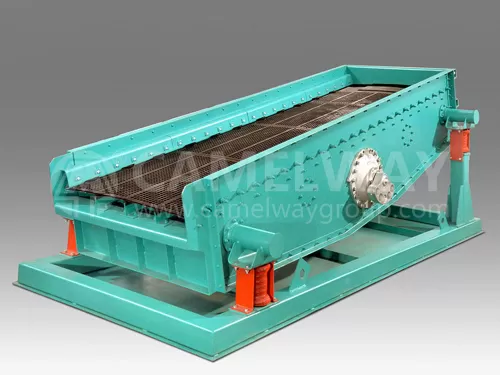

There are two types of vibrating screen in Hongji Mine Machinery, namely, round or circular vibrating screen and linear vibrating screen. The following pictures are round vibrating screen and linear vibrating screen.

The round vibrating screen should be started without materials on the screen surface, and it should be fed with materials after beginning stable operation. Before stopping it, first stop feeding, and after all the materials are screened out, then stops the machine. In the working process, regularly observe the running condition of the round vibrating screen, if there is anything abnormal or there is abnormal sound, immediately stop the machine to check it, find out the reason and eliminate the failure.

The Operation and Maintenance of Circular Vibrating Screen

The circular vibrating screen should be started with no materials on the screen surface and materials can be fed once the screen runs stably. Before we shut down the machine, we should prior stop feeding materials and make sure that the materials are discharged clearly on the screen surface. Users should observe the operating condition of the vibrating screen while it's running. If there is abnormal case or sound appearing, users must shut down the machine immediately to find out the reason and remove the trouble.

The circular vibrating screen made by CamelWay Machinery company has plenty of advantages: compact structure, strong exciting force, high screening efficiency, little vibrating noise, durability, simple maintenance and safe operation etc. Its productivity has reached the national standard and ranks the advanced international level. Our circular vibrating screen has been praised by customers in all industries.

Note

- The production capacity is measured in the laboratory under standard conditions, and is generally smaller in actual construction.

- Power refers to the average power, for reference only. Please be sure to contact us for advice before planning power supply.

- Container Qty refers to the number of containers required under standard configuration.

- Price refers EX reference Price, please contact us for the latest price and possible discounts.

- All product parameters provided are for reference only, and we reserve the right to change without notice.

GET QUOTE

GET QUOTE  WHATSAPP

WHATSAPP

0 Review