Introduce

Vibrating feeder is known as vibratory feeder or vibration feeder. Vibrating feeder or vibration feeder can give the massive and granular materials from storage to the material receiving device evenly, timely and continuously. In gravel crushing plant, vibratory feeder or vibration feeder can be evenly and timely feed materials for the crushing machines and do coarse screening of materials, which are widely used in metallurgical, coal mine, ore dressing, building materials, chemical and other industries.

Vibrating feeder also can be called feeding machine in the mining industry. Vibrating feeder is one key machine used for conveying the raw material whose size is the cube to the feed inlet with the smooth speed. Feeder machine applied in the sand production line and stone production line can feed the raw material for the crushing machine and sand maker, which can be broadly applied in the industries such as the sandstone producing, ore dressing, building material and the chemical industry.

Vibrating Feeder can feed the lump, grayness material evenly and continuously to the accepting set. In sand making line, vibrating feeder can evenly and continuously feed the material preventing the blockage of crusher feeding mouth. Vibrating feeder has features of simple structure and operation, no need for lubricant and low power consumption; it can modify the feeding quantity evenly. It is widely used in mine, macadam court, metallurgy,construction, chemical, mine, core industry, etc.

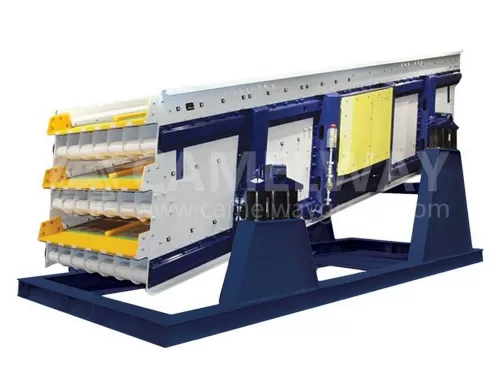

The Structure of Vibrating Feeder

Vibrating feeder or vibrating grizzly feeder consists of feeding tank, vibration exciter, spring bearing, transmission parts and other components. In sand production line, the vibrating grizzly feeder can evenly and continuously feed materials for crushers so as to avoid the clogging of the material receiving port.

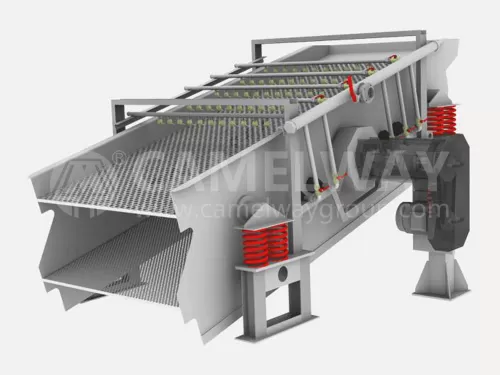

The Working principle of Vibrating Feeder

By taking advantage of the centrifugal force generated by rotating of eccentric block of vibration exciter. Vibrating feeder conducts the movement of a continuous circle or approximate circular. Through the vibration of the tank, materials are flowed continuously so as to realize the purpose of conveying materials.

The Features of Vibrating Feeder

Vibratory feeder is economic and advanced feeding equipment with best technical indicators, compared with other feeding equipment,Hongji vibrating feeder has the following characteristics:

1. Small volume, the weight is light and the structure is simple;

2. Easy installation and maintenance, low operation cost;

3. High efficiency, large feeding capacity;

4. Low noise, it helps to improve the working environment;

5. Low power consumption, high power factor;

6. Hongji vibrating feeder is with resonance and amplitude stability, and high reliability.

The Advantages of Vibrating Feeder

1. Smooth vibration; reliable operation.

2. Adjustable gate gap.

3. More wear-resistant parts

4. A special grid is designed to prevent material clogging.

5. Optional variable-frequency adjustable-speed motor, frequency, thus changing the output, easy to control feeding amount, having to constantly start a motor.

6. High start frequency.

Note

- The production capacity is measured in the laboratory under standard conditions, and is generally smaller in actual construction.

- Power refers to the average power, for reference only. Please be sure to contact us for advice before planning power supply.

- Container Qty refers to the number of containers required under standard configuration.

- Price refers EX reference Price, please contact us for the latest price and possible discounts.

- All product parameters provided are for reference only, and we reserve the right to change without notice.

GET QUOTE

GET QUOTE  WHATSAPP

WHATSAPP

0 Review